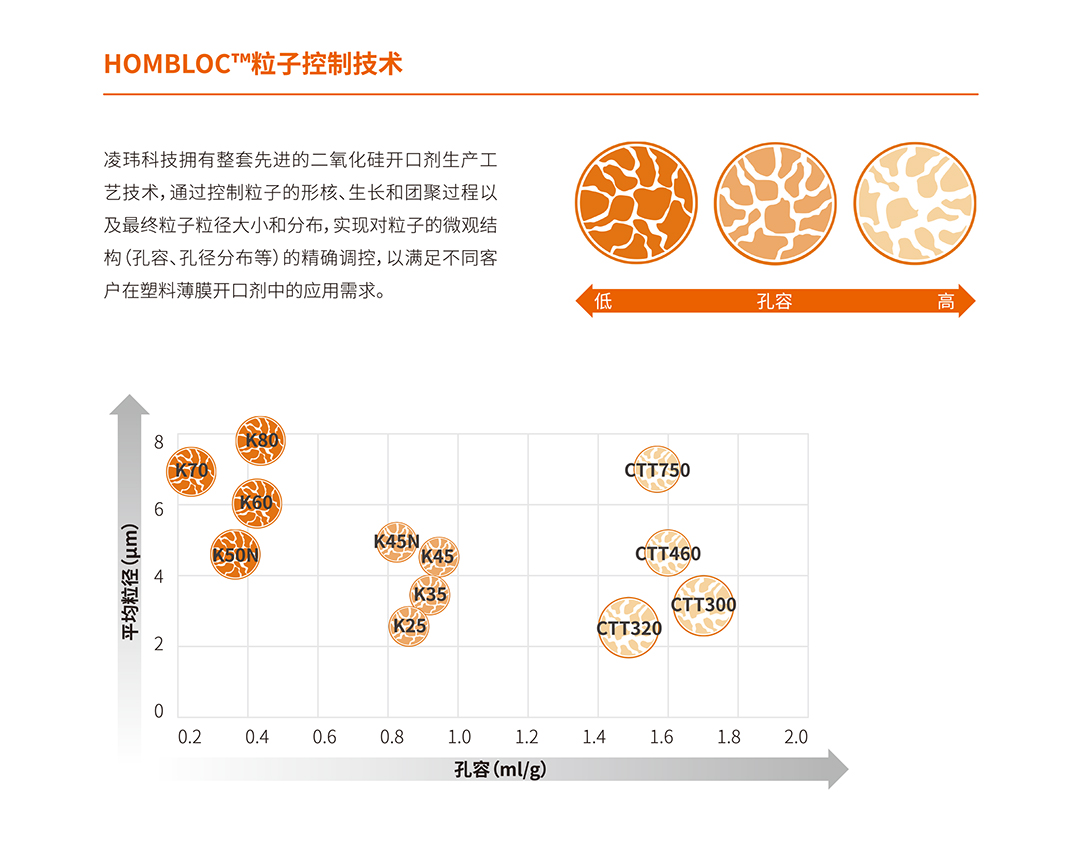

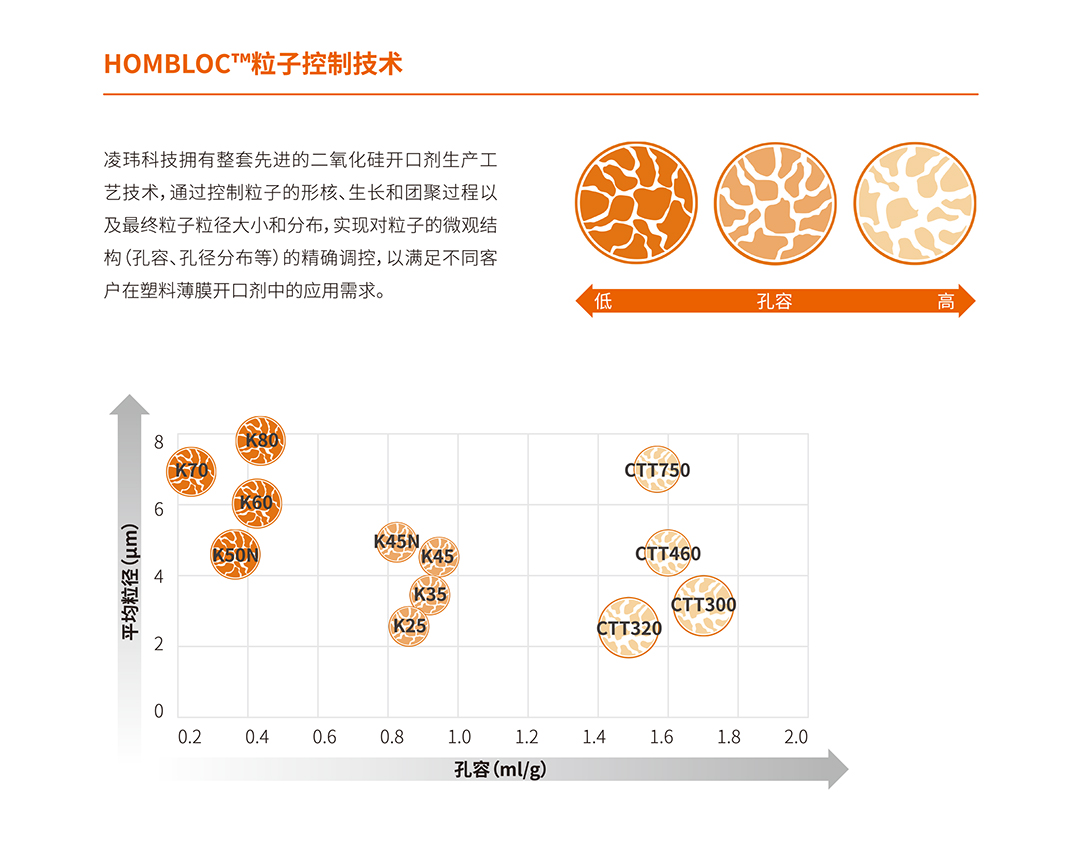

Polyester film (PET)

Polyester film (PET) : HOMBLOC™ reduces the "adhesion" effect between film layers during the production process through particle microstructure control, effectively maintaining the original optical properties of the film while resisting "adhesion".

- 【Optical film】Recommended model: CTT300

- 【Matte film】Recommended models: CTT320, K35, K45

Polypropylene film (PP) : HOMBLOC™ reduces the mesh pressure of the screw extruder filter through the pore volume, narrow particle size distribution and surface modification, ensuring efficient masterbatch production. Through the unique pore structure, the friction coefficient of the film surface is significantly reduced, making the downstream production process smoother, improving the overall production efficiency and film quality.

- 【CPP film】Recommended models: K35, K45, K45N

- 【BOPP film】Recommended models: K25, K35, K45, K45N

Polyethylene film (PE) : HOMBLOC™ has a purity of up to 99% to meet high concentration masterbatch requirements; Compatible with PE film resin, low staining risk. By controlling the particle size distribution, the accumulated net pressure of the extruder screen filter is reduced, and the service life of the extruder screen is effectively extended.Recommended models: K50N、K70、K80